The va comonomer interferes with chain packing reducing crystallinity and thus lowering t m and improving transparency when compared with ldpe.

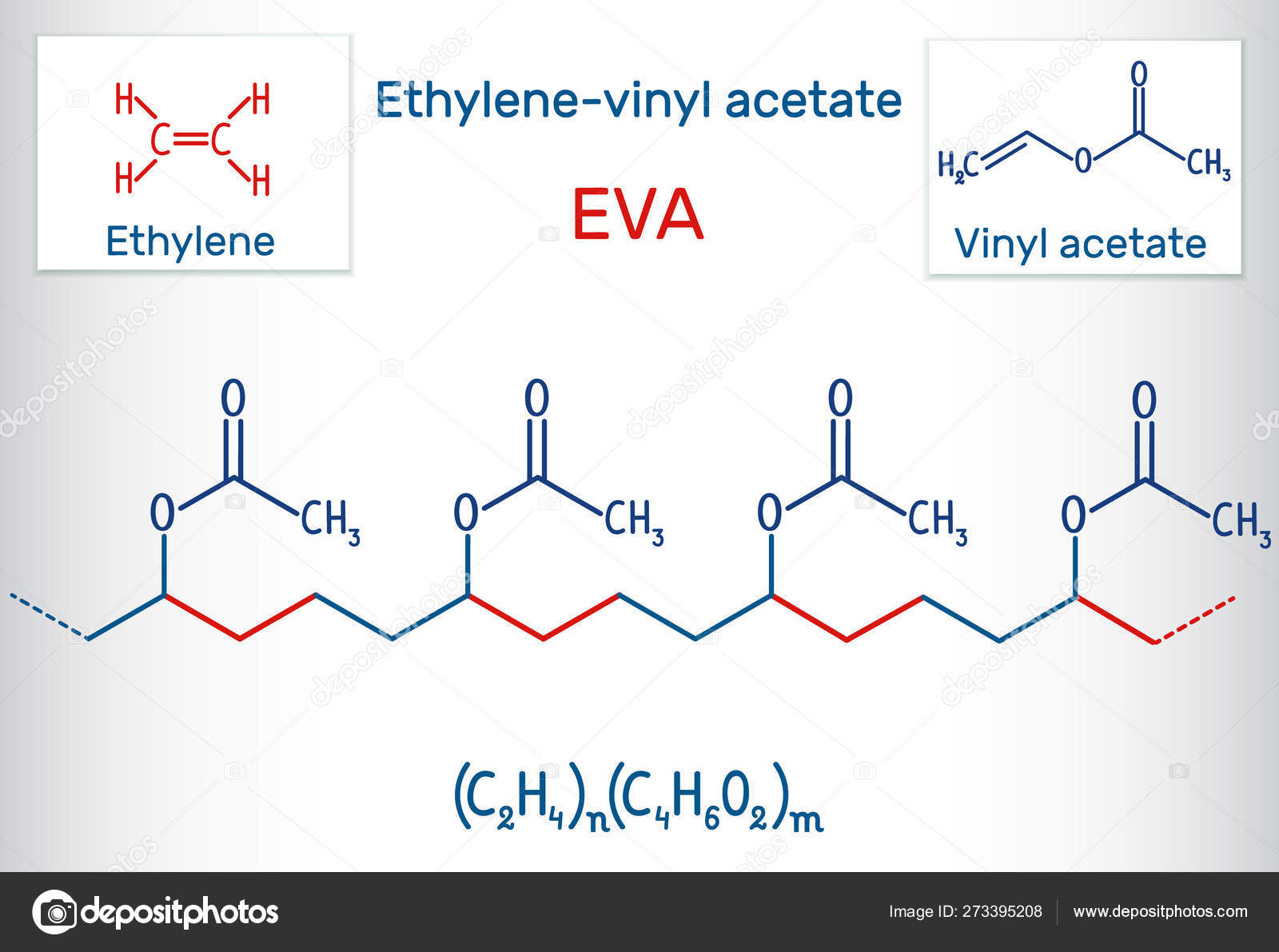

Molecular weight of ethylene vinyl acetate.

Ethylene vinyl acetate polymer.

Ethylene vinyl acetate copolymer eva for instance is produced by the copolymerization of ethylene and vinyl acetate under pressure using free radical catalysts.

Vam is usually produced by the catalysed vapour phase reaction of acetic acid with ethylene and oxygen in a fixed bed tubular reactor using a supported noble metal catalyst.

There are three different types of eva copolymer which differ in the vinyl acetate va content and the way the materials are used.

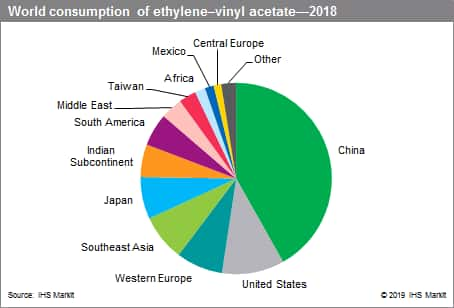

The following pie chart shows world consumption of ethylene vinyl acetate.

World eva capacity is projected to increase at an average annual rate of about 5 per year through 2023 while consumption is expected to increase at 4 per year over the same period.

Emblem in packaging technology 2012.

As the va content increases crystallinity decreases until at 50 the eva is.

Ethylene is now the preferred feedstock for vam vinyl acetate monomer largely replacing the earlier acetylene based process.

Ethylene vinyl acetate eva is a random copolymer of ethylene and varying amounts of vinyl acetate va.