The operating temperature and partial pressure of an impurity along with the type of molecular sieve 3a 4a 5a 13x defines the adsorption capacity of that impurity.

Molecular sieve dryer design.

This information is primarily concerned with the sizing of dryer units.

A number of parameters influence the design and operation of a molecular sieve unit.

Herold contributing writer amsterdam the netherlands.

Molecular sieve technology is widely used for the simultaneous removal of water and mercaptans from both gas and liquid feed streams.

As a brief overview on molecular sieve dryer.

In addition to these design guidelines there are additional considerations in liquid dryer design.

A molecular sieve works by adsorbing gas or liquid molecules that are smaller than the effective diameter of its pores while excluding those molecules that are larger than the openings.

Optimal design and operation of molecular sieve gas dehydration units part 1.

These pore diameters are similar in size to small molecules and thus large molecules cannot enter or be adsorbed while smaller molecules can as a mixture of molecules migrate through the stationary bed of porous semi solid substance referred to as a sieve or matrix the components of highest molecular weight.

A practical example of the function of molecular sieves is to dry ethanol.

Table 2 is a compilation of some suggested design guidelines extracted from commercial information on desiccant dryers.

Mole sieve switching valve de hydration switching valve gas de hy switching valve among others.

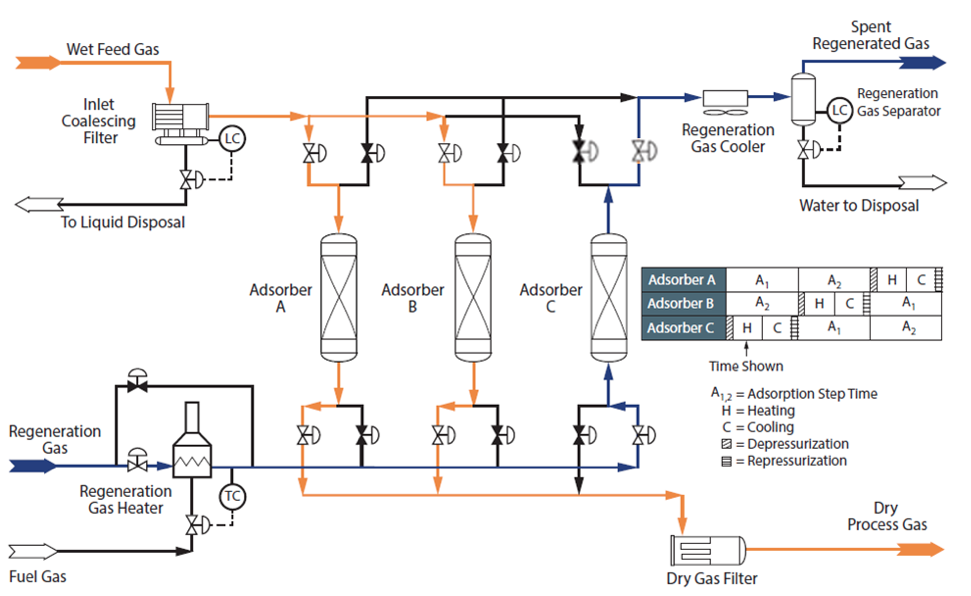

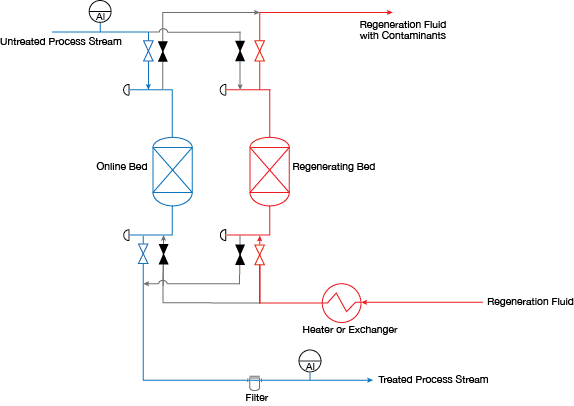

A cyclical adsorption desorption system to transfer contaminants or non desired gas molecules from one stream to another.

A molecular sieve is a material with pores very small holes of uniform size.

The targeted valve installation is a molecular sieve dryer valve also known as.

Molecular sieve adsorbents are available in the following forms 3a k na zeolite a with a nominal pore opening of 3 å 0 3 nm 4a as synthesized na zeolite a with a nominal pore opening of 4 å 0 4 nm 5a ca na zeolite a with a nominal pore opening of 5 å 0 5 nm 13x na zeolite x with a nominal pore opening of 10 å 1 0 nm properties of basf molecular.

Jalon molecular sieve for desiccant air dryer 4a and standard activated alumina provide the ideal combination of strength and adsorption capacity to produce reliable dry air that is reliable without causing equipment damage.

As it ages molecular sieve releases particulates that can be very damaging to downstream processes and instrumentation.

Mokhatab gas processing consultant halifax nova scotia canada.

Our molecular sieve for desiccant air dryer is a low dust.